Friday, 19 April 2013

Scale Prototype

Due to the lack of appropriate materials, the scale prototype does not include the metal rods which act as the seating plane.

This 1:5 scale model is made from a single cardboard net, cut and folded to produce this shape. This model has opened up the possibility of perhaps replicating the net and making it out of laser cut steel for the full sized prototype, instead of wood. The advantage of having a laser cut steel sheet may be in reducing the overall mass and also increasing the precision of hole alignment for the steel rods, by reducing the tolerances often attributed to human error during manufacturing with wood.

This 1:5 scale model is made from a single cardboard net, cut and folded to produce this shape. This model has opened up the possibility of perhaps replicating the net and making it out of laser cut steel for the full sized prototype, instead of wood. The advantage of having a laser cut steel sheet may be in reducing the overall mass and also increasing the precision of hole alignment for the steel rods, by reducing the tolerances often attributed to human error during manufacturing with wood.

Further Concept Development

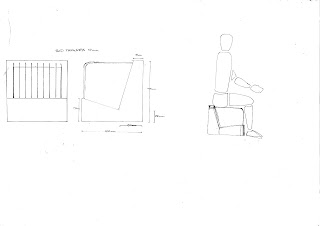

Considering the potential difficulty of actually being able to make a prototype of my previous preferred outcome from the ideation, I have developed my second favourite design, which I believe to be a more achievable design, considering the time constraints on this project and also my metal working know-how.

For this design I explored what possible shapes can be made within the 400mm^3 volume stool. I preferred to keep the walls of the design all perpendicular to the ground as to keep within the cube shape.

I also considered the ability of all of the sub-varieties of this stool to be stacked, as is helpful in a cafe, the most likely setting for such a stool.

I also considered the ability of all of the sub-varieties of this stool to be stacked, as is helpful in a cafe, the most likely setting for such a stool.

I do not yet know what sizes of steel rods are available to me, so I have not yet decided on how many will be included in the final design.

Friday, 12 April 2013

Scale Prototype

The images above are of a scale model of my preferred design outcome. The scale of the model is 1:5 and is made from construction paper. Despite the material the structure is strong and can balance weight quite well, though I believe it may help to add supports behind the hanging columns to strengthen it in the axis running perpendicular to the curved seating plane. The final 1:1 scale prototype will likely have to be made from sheet steel and due to the small radius in the curve lines, will most likely require some cutting to aid bending.

I worked on various shapes and sizes for this particular stool until I was happy with how it was proportioned. The dimensions of the single sheet of construction paper I used to make this are 380mm x 80mm. The radius of the curved surface is 110mm and the length and width of the columns are 50mm by 20mm.

Tuesday, 9 April 2013

Tuesday, 2 April 2013

Material Experimentation: Cardboard

To better demonstrate how lightweight materials can support a disproportionately large mass, I created two structures out of cardboard, using curved bend lines to create curved surfaces. This enabled the cardboard structures to support hundreds of times its own mass. The design in the top photo was the heaviest of the two, using multiple pieces cardboard. This design was the most stable, however it could not handle as much weight as the design in the second photo, this is because the surfaces supporting the mass during testing were not curved enough; after minor changes to the design (increasing the crown in the surfaces) the structure was able to support more weight. The design in the second photo was able to support the most weight, whilst still being the lightest, having only been made from a single piece of cardboard. The one problem this design did make very apparent was that the mass was not being distributed in such a way that did not cause buckling and twisting.

From this I learned that reinforcement of materials is not always the best way to strengthen a structure. It has become clear that clever design, through smart material choices and adjusting curvature can drastically improve results, especially when the mass of a piece of furniture is of great concern, second only to the safety of the person using the product.

Monday, 18 March 2013

Lightweight Material Research

Material Research: This post will contain the average densities of various forms of common materials, possible processes for manufacturing furniture, some of their properties relevant to their functional application as a component of a piece of furniture and their aesthetic properties as well.

Plastics

Common

Forms

|

Sheets

|

Tubes/Rods

|

Mesh

|

Avg.

Density (gcm-3)

|

0.800-1.500

|

||

Manufacturing

Processing for furniture

|

Vacuum forming , line bending, cutting, bolting.

|

Bending

|

Line bending, cutting

|

Properties

|

High tensile strength, flexible, reflective,

generally quite light weight. Form can be manipulated to strengthen

structures.

|

||

Aesthetics

|

All can be glossy or matt, which reflects light in various ways. Many

colours are available

|

||

Wood

Common

Forms

|

Solid

Timber

|

Laminated

Veneer

|

Plywood

|

Avg.

Density (gcm-3)

|

.600-1.200

|

0.500-0.800

|

.500-.900

|

Manufacturing

processing for furniture

|

May be cut, carved

|

May be bent, glued, ironed, twisted

|

May be bent, cut

|

Properties

|

Strong, rigid.

|

Flexible, brittle

|

Strong, somewhat flexible

|

Aesthetics

|

All may be painted, lacquered, veneered, or left natural

|

||

Steel

Common

Forms

|

Sheet

|

Tube

|

Perforated

Sheet

|

Density

(gcm-3)

|

7.750-8.050

|

||

Manufacturing

Processing for furniture

|

Sheets can be

rolled, cut, bent to increase structural rigidity. Steel must be welded or

bolted to connect parts.

|

Tubes can be curved,

cut and welded.

|

Perforated sheets can

be rolled, cut, bent to increase structural rigidity. Steel must be welded or

bolted to connect parts.

|

Properties

|

Malleability, shaping

can increase structural integrity

|

High strength,

durability

|

Malleability, shaping

can increase structural integrity, perforation maintains considerable strength

and reduces weight of sheet

|

Aesthetics

|

Plain metallic

surface, can be painted, or decorated with cutting out parts of the surface.

|

Surface can reflect

light, can be painted. Industrialized look.

|

Has uniform pattern,

may be painted, industrial look.

|

Paper

Common

Forms

|

Paper

Mache

|

Molded

Pulp

|

Layered

& glued

|

Avg.

Density (gcm-3)

|

0.400-1.500 (depending

on other constituents)

|

||

Manufacturing

Processes for furniture

|

Gluing, cutting

|

Pulping, casting, compression, cutting

|

Gluing, cutting

|

Properties

|

Somewhat flexible, low tensile strength,

lightweight, may need reinforcement

|

||

Aesthetics

|

Can be painted, not reflective (excluding paper mache)

|

||

Fabrics

Typically fabrics are not used as structural components in ,

due to their inability to maintain structural integrity under compressive

forces, with the exception of woven fiberglass sheets and hemp fiber paneling.

Instead the fabrics are used to make the seating, as they are generally good at

distributing load evenly and have high tensile strengths whilst being able to

stretch and bend. Examples of fabrics include: Leather, suede, wool, silk,

cotton, hemp, fiberglass, spandex, nylon, acrylic and polyester. Depending on thickness, these materials have a varied density range.

Strings, ropes, hoses and wires are all specifically

designed to withstand tension and fail to maintain shape under compression, much

like fabrics. Wires however tend to be much stronger under compression, given

the shape has appropriately been manipulated to allow for compression to be

withstood. Generally all of these materials are used for the seating in

furniture and exhibit the highest tensile strength when woven together.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.JPG)